一、金剛線切割工藝原理是什么

金剛線主要用于光伏晶硅等硬脆材料切割,是光伏硅片重要的耗材設備,現在常用的一般是電鍍金剛線,那么金剛線的切割原理(li)是什(shen)么呢?

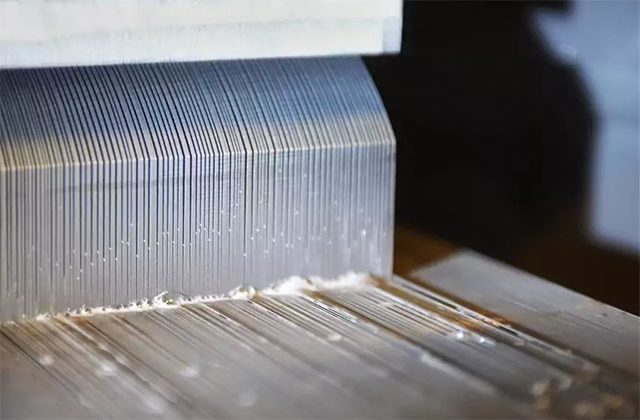

金剛線(xian)由(you)母(mu)線(xian)、金屬鎳層(ceng)、金剛石(shi)顆(ke)(ke)粒三部分組成,以母(mu)線(xian)作(zuo)(zuo)為(wei)(wei)承載基(ji)體,金剛石(shi)顆(ke)(ke)粒作(zuo)(zuo)為(wei)(wei)磨粒刀具,金屬鍍層(ceng)作(zuo)(zuo)為(wei)(wei)結合劑將金剛石(shi)顆(ke)(ke)粒固(gu)結在母(mu)線(xian)上(shang);切(qie)割(ge)時,金剛線(xian)靠近被(bei)切(qie)割(ge)的(de)材料(如硅棒(bang)或硅片),并通過高速旋轉和研(yan)磨劑的(de)使用(yong),產(chan)生磨削(xue)效(xiao)果,從而實現切(qie)割(ge)。

二、金剛石線切割工藝中的核心技術有哪些

金(jin)剛(gang)線(xian)切割(ge)技(ji)術仍將作為未來相當長一段(duan)時間內主流的(de)硅片(pian)切割(ge)技(ji)術,它的(de)切割(ge)工藝主要(yao)應用了以(yi)下16種技(ji)術:

1、高精度切割線管理技術

以金(jin)(jin)剛線(xian)(xian)(xian)(xian)(xian)切片(pian)機為例,切片(pian)機工作(zuo)過程中,金(jin)(jin)鋼(gang)線(xian)(xian)(xian)(xian)(xian)高速(su)(su)從放線(xian)(xian)(xian)(xian)(xian)輥(gun)放出,經(jing)過排(pai)線(xian)(xian)(xian)(xian)(xian)輪(lun)、張(zhang)力(li)輪(lun)、過線(xian)(xian)(xian)(xian)(xian)輪(lun)和切割(ge)軸后,收(shou)(shou)(shou)回纏繞(rao)到(dao)收(shou)(shou)(shou)線(xian)(xian)(xian)(xian)(xian)輥(gun)上(shang)(shang);再反方向由收(shou)(shou)(shou)線(xian)(xian)(xian)(xian)(xian)輥(gun)繞(rao)回到(dao)放線(xian)(xian)(xian)(xian)(xian)輥(gun),金(jin)(jin)剛線(xian)(xian)(xian)(xian)(xian)高速(su)(su)往復雙向運動(dong)。原則(ze)上(shang)(shang)切片(pian)機工作(zuo)過程中,收(shou)(shou)(shou)線(xian)(xian)(xian)(xian)(xian)、放線(xian)(xian)(xian)(xian)(xian)及排(pai)布(bu)線(xian)(xian)(xian)(xian)(xian)須(xu)同(tong)步且(qie)金(jin)(jin)剛線(xian)(xian)(xian)(xian)(xian)所(suo)受到(dao)的(de)(de)張(zhang)力(li)應保持(chi)穩(wen)定(ding),然而收(shou)(shou)(shou)、放線(xian)(xian)(xian)(xian)(xian)輥(gun)上(shang)(shang)繞(rao)制(zhi)的(de)(de)金(jin)(jin)剛線(xian)(xian)(xian)(xian)(xian)卷徑是隨時變化的(de)(de),必須(xu)實時控(kong)制(zhi)收(shou)(shou)(shou)、放線(xian)(xian)(xian)(xian)(xian)輥(gun)的(de)(de)轉速(su)(su)以保證(zheng)高速(su)(su)運動(dong)的(de)(de)金(jin)(jin)剛線(xian)(xian)(xian)(xian)(xian)的(de)(de)線(xian)(xian)(xian)(xian)(xian)速(su)(su)度(du)穩(wen)定(ding)且(qie)保持(chi)金(jin)(jin)剛線(xian)(xian)(xian)(xian)(xian)所(suo)受到(dao)的(de)(de)張(zhang)力(li)穩(wen)定(ding);同(tong)時還需要保證(zheng)排(pai)線(xian)(xian)(xian)(xian)(xian)裝(zhuang)置(zhi)與收(shou)(shou)(shou)放線(xian)(xian)(xian)(xian)(xian)輥(gun)同(tong)步。

2、高精度張力控制技術

以(yi)金剛線(xian)(xian)切片(pian)機為例,切片(pian)機切割(ge)硅(gui)(gui)棒過程中,金剛線(xian)(xian)須保持穩(wen)(wen)定的(de)切割(ge)張力(li),若(ruo)(ruo)張力(li)過小,將導致(zhi)(zhi)(zhi)金剛線(xian)(xian)切割(ge)力(li)不足;若(ruo)(ruo)張力(li)過大,將導致(zhi)(zhi)(zhi)金剛線(xian)(xian)斷線(xian)(xian);若(ruo)(ruo)張力(li)控制(zhi)不穩(wen)(wen)定,或將導致(zhi)(zhi)(zhi)切出的(de)硅(gui)(gui)片(pian)存在TTV超標、線(xian)(xian)痕(hen)明顯、硅(gui)(gui)片(pian)彎曲和翹(qiao)曲等質量問題(ti),嚴重時金剛線(xian)(xian)斷線(xian)(xian)或將導致(zhi)(zhi)(zhi)整(zheng)根硅(gui)(gui)棒損壞(huai)。因此,精(jing)確、靈敏(min)、穩(wen)(wen)定、無擾動的(de)切割(ge)線(xian)(xian)張力(li)控制(zhi)技術是金剛線(xian)(xian)切割(ge)技術的(de)關鍵技術之一。

3、高精度夾持進給技術

切割(ge)(ge)設備工(gong)作時需(xu)要夾持(chi)被加(jia)工(gong)材料與切割(ge)(ge)刀(dao)具持(chi)續、穩定(ding)、緊密接觸,被加(jia)工(gong)材料進給的穩定(ding)性直接影響(xiang)到(dao)切割(ge)(ge)的質量和效率;因(yin)此,夾持(chi)進給系(xi)統(tong)須具有高定(ding)位精度、高動態響(xiang)應、高穩定(ding)性等特點。

4、多主軸動態平衡控制技術

單(dan)(dan)晶(jing)硅圓(yuan)棒開方(fang)時,金剛(gang)線(xian)切(qie)割線(xian)網是(shi)由(you)一根(gen)金剛(gang)線(xian)布(bu)成的(de)(de)井字形線(xian)網,需要運用(yong)多(duo)(duo)主軸動(dong)態平(ping)衡(heng)控制技術(shu)來(lai)進行布(bu)線(xian)控制,以保證開方(fang)機(ji)線(xian)網的(de)(de)穩定運行。公(gong)司經過多(duo)(duo)年的(de)(de)自(zi)主研發、實踐及持續優化,率(lv)先將自(zi)主研發的(de)(de)多(duo)(duo)主軸動(dong)態平(ping)衡(heng)控制技術(shu)應用(yong)于金剛(gang)線(xian)單(dan)(dan)晶(jing)開方(fang)機(ji),使(shi)得金剛(gang)線(xian)單(dan)(dan)晶(jing)開方(fang)機(ji)主軸輪(lun)使(shi)用(yong)壽命延長、斷線(xian)率(lv)降低、切(qie)割成本降低。

5、高精度晶線檢測技術

晶(jing)線(xian)檢(jian)測(ce)是單晶(jing)硅(gui)(gui)棒(bang)(bang)(bang)開方的重要工序,晶(jing)線(xian)檢(jian)測(ce)的成(cheng)功與否,會(hui)直(zhi)(zhi)接影響(xiang)切(qie)(qie)割(ge)質量(liang)和(he)切(qie)(qie)割(ge)效率(lv)。如(ru)(ru)果晶(jing)線(xian)檢(jian)測(ce)錯誤且繼續切(qie)(qie)割(ge)動作(zuo),會(hui)造成(cheng)硅(gui)(gui)棒(bang)(bang)(bang)直(zhi)(zhi)接報廢;如(ru)(ru)果檢(jian)測(ce)用(yong)時(shi)過多,會(hui)降低(di)切(qie)(qie)割(ge)效率(lv)。高精(jing)(jing)度(du)晶(jing)線(xian)檢(jian)測(ce)技術,利用(yong)高精(jing)(jing)度(du)傳感(gan)器、多層控制算法(fa)、閉環自動調整技術,可以(yi)保證硅(gui)(gui)棒(bang)(bang)(bang)誤切(qie)(qie)率(lv)趨(qu)近于零,晶(jing)線(xian)檢(jian)測(ce)成(cheng)功率(lv)達99.9%,大幅度(du)縮短了晶(jing)線(xian)檢(jian)測(ce)時(shi)間

6、超薄片切割工藝技術

該技術是通過優化切割工藝匹配、優化切割設備部套性能,實現高硬脆材料的薄片切割,從而降低成品片所需材料用量、提升成品片柔韌性的切割工藝技術。以光伏(fu)用單晶硅片(pian)為(wei)例(li),超薄片(pian)技術(shu)路線是面向光伏(fu)平價上網(wang)的主要解決方(fang)案之一(yi),針對下(xia)一(yi)代電(dian)池技術(shu)具(ju)有(you)明顯的性價比(bi)優勢,片(pian)厚(hou)的下(xia)降帶來硅片(pian)柔性的提高,組件的應(ying)用場景也相應(ying)提升,高轉(zhuan)換效率和低成本的材(cai)料有(you)利于客(ke)戶產品提升競爭力。

7、基于大數據算法的切割過程工藝自適應技術

該(gai)技術通過算法、數據、切(qie)(qie)割(ge)工藝調整邏輯(ji),使得(de)切(qie)(qie)割(ge)類設備(bei)(bei)在一定程度上(shang)具備(bei)(bei)模擬切(qie)(qie)割(ge)工藝人員對切(qie)(qie)割(ge)過程出現的復雜問(wen)題的識(shi)別(bie)、學(xue)習和解決能力,使得(de)切(qie)(qie)割(ge)裝備(bei)(bei)智能地針對切(qie)(qie)割(ge)過程中(zhong)遇到(dao)的金剛(gang)線(xian)、輔(fu)料(liao)、裝備(bei)(bei)等出現的異常情況給出快(kuai)速(su)、精確、可(ke)重復的處理措施,從而降低斷線(xian)率、提升(sheng)生(sheng)產效率、提高切(qie)(qie)片良率。

8、超細金剛線高線速切割工藝技術

該(gai)技術(shu)是通過優化金(jin)剛線切(qie)(qie)割相關工(gong)藝(yi)參數(shu),力求使(shi)用(yong)線徑(jing)更細(xi)的(de)金(jin)剛線切(qie)(qie)割,從而降低(di)制造硅片(pian)所需的(de)材料(liao)用(yong)量、提(ti)升切(qie)(qie)片(pian)良率(lv)、提(ti)高(gao)切(qie)(qie)割生產效率(lv)、降低(di)固定資產投資成本的(de)切(qie)(qie)割工(gong)藝(yi)技術(shu)。

9、高精度軸承箱設計制造技術

以金剛線切片機為例,切片機兩根切割主輥帶動金剛線網在硅棒表面高速往復磨削,將硅棒切削加工為硅片。兩根切割主輥由軸承支撐起來高速旋轉,軸承則安裝在兩根主輥前后四個軸承箱中。切割主輥轉動產生的軸向和徑向力將導致切片機在微米級切割狀態下出現切割精度波動,并進而影響生產效率及硅片質量。軸(zhou)(zhou)(zhou)(zhou)承(cheng)箱在上述(shu)切割主軸(zhou)(zhou)(zhou)(zhou)工作(zuo)過程中(zhong)起到支撐和保持精(jing)度(du)的關(guan)鍵(jian)作(zuo)用,一方面(mian),切割主輥將高速(su)旋(xuan)轉工作(zuo)時(shi)承(cheng)受的軸(zhou)(zhou)(zhou)(zhou)向和徑(jing)向力傳遞到軸(zhou)(zhou)(zhou)(zhou)承(cheng)箱上,由(you)軸(zhou)(zhou)(zhou)(zhou)承(cheng)箱的力學結(jie)構承(cheng)載并化解;另一方面(mian),軸(zhou)(zhou)(zhou)(zhou)承(cheng)箱精(jing)度(du)和剛度(du)保證了金剛線(xian)網的運行精(jing)度(du),從而保證了硅片切割質量。

10、高穩定性液路技術

在(zai)(zai)金剛線(xian)切(qie)片(pian)機(ji)工作(zuo)過程中,金剛線(xian)切(qie)割(ge)硅(gui)片(pian)時會持(chi)續產生(sheng)大量(liang)的熱(re)量(liang),若大量(liang)熱(re)聚集則會使高精度軸(zhou)承(cheng)箱和硅(gui)棒發(fa)生(sheng)熱(re)變形,進而降(jiang)低(di)切(qie)片(pian)機(ji)的工作(zuo)精度、降(jiang)低(di)硅(gui)片(pian)的質量(liang)。因此,軸(zhou)承(cheng)箱和硅(gui)棒所(suo)在(zai)(zai)的切(qie)割(ge)區域(yu)需進行循環冷(leng)卻,以(yi)帶走(zou)切(qie)割(ge)硅(gui)棒產生(sheng)的熱(re)量(liang),并保(bao)證切(qie)割(ge)區域(yu)溫度恒定。

11、低張力高效上砂技術

“低(di)張(zhang)(zhang)力(li)高效上(shang)砂(sha)技術(shu)”主(zhu)(zhu)(zhu)要是指(zhi)“分(fen)(fen)段(duan)(duan)張(zhang)(zhang)力(li)系(xi)統”和“單(dan)機(ji)(ji)(ji)(ji)十二線設計(ji)技術(shu)(原單(dan)機(ji)(ji)(ji)(ji)六線設計(ji)技術(shu))”。“分(fen)(fen)段(duan)(duan)張(zhang)(zhang)力(li)系(xi)統”是指(zhi)在金(jin)剛線生產線主(zhu)(zhu)(zhu)要工藝(yi)(yi)段(duan)(duan)設置驅動電(dian)(dian)機(ji)(ji)(ji)(ji)和張(zhang)(zhang)力(li)電(dian)(dian)機(ji)(ji)(ji)(ji),中間工藝(yi)(yi)段(duan)(duan)電(dian)(dian)機(ji)(ji)(ji)(ji)為主(zhu)(zhu)(zhu)軸(zhou)電(dian)(dian)機(ji)(ji)(ji)(ji),其他(ta)電(dian)(dian)機(ji)(ji)(ji)(ji)為從軸(zhou)跟(gen)隨主(zhu)(zhu)(zhu)軸(zhou)同(tong)步,金(jin)剛線生產線各(ge)工藝(yi)(yi)段(duan)(duan)的鋼線張(zhang)(zhang)力(li)控制(zhi)是獨立的,從而可以實現低(di)張(zhang)(zhang)力(li)上(shang)砂(sha),減少鋼線因大張(zhang)(zhang)力(li)磨損而導致的脫砂(sha)情況,有利于高質量上(shang)砂(sha)。

12、機器視覺圖像識別技術

“機器視覺圖(tu)像識(shi)別系統(tong)”通過高速工(gong)業(ye)像機在(zai)(zai)線(xian)實(shi)(shi)(shi)時(shi)(shi)(shi)拍(pai)攝固結在(zai)(zai)鋼(gang)線(xian)基體上單(dan)位(wei)視野內的(de)(de)金(jin)剛(gang)(gang)石(shi)微(wei)粉(fen)顆粒(li)的(de)(de)顯微(wei)圖(tu)像,圖(tu)像信(xin)(xin)號(hao)實(shi)(shi)(shi)時(shi)(shi)(shi)傳送給圖(tu)像處(chu)理(li)系統(tong)并(bing)(bing)轉換為數(shu)(shu)(shu)(shu)字(zi)化信(xin)(xin)號(hao),數(shu)(shu)(shu)(shu)字(zi)化的(de)(de)圖(tu)像信(xin)(xin)號(hao)被(bei)金(jin)剛(gang)(gang)線(xian)生(sheng)(sheng)產(chan)(chan)線(xian)檢(jian)測(ce)控(kong)制(zhi)系統(tong)實(shi)(shi)(shi)時(shi)(shi)(shi)接(jie)收(shou),并(bing)(bing)實(shi)(shi)(shi)時(shi)(shi)(shi)計算(suan)鋼(gang)線(xian)基體上單(dan)位(wei)視野內的(de)(de)金(jin)剛(gang)(gang)石(shi)微(wei)粉(fen)顆粒(li)數(shu)(shu)(shu)(shu)量(liang)、分(fen)布(bu)均勻性的(de)(de)分(fen)析數(shu)(shu)(shu)(shu)據,從而(er)實(shi)(shi)(shi)現(xian)對金(jin)剛(gang)(gang)線(xian)上固結的(de)(de)金(jin)剛(gang)(gang)石(shi)微(wei)粉(fen)顆粒(li)數(shu)(shu)(shu)(shu)量(liang)、分(fen)布(bu)均勻性的(de)(de)實(shi)(shi)(shi)時(shi)(shi)(shi)在(zai)(zai)線(xian)檢(jian)測(ce),并(bing)(bing)將(jiang)實(shi)(shi)(shi)時(shi)(shi)(shi)在(zai)(zai)線(xian)檢(jian)測(ce)數(shu)(shu)(shu)(shu)據與生(sheng)(sheng)產(chan)(chan)工(gong)藝(yi)設定(ding)數(shu)(shu)(shu)(shu)據比較(jiao),實(shi)(shi)(shi)時(shi)(shi)(shi)調(diao)整金(jin)剛(gang)(gang)線(xian)生(sheng)(sheng)產(chan)(chan)線(xian)的(de)(de)生(sheng)(sheng)產(chan)(chan)工(gong)藝(yi)參數(shu)(shu)(shu)(shu),進(jin)而(er)實(shi)(shi)(shi)現(xian)對金(jin)剛(gang)(gang)線(xian)上固結的(de)(de)金(jin)剛(gang)(gang)石(shi)微(wei)粉(fen)顆粒(li)數(shu)(shu)(shu)(shu)量(liang)、分(fen)布(bu)均勻性的(de)(de)實(shi)(shi)(shi)時(shi)(shi)(shi)控(kong)制(zhi)。

13、砂量模糊控制技術

“砂量模(mo)糊控制系統(tong)”以金剛線生產大數(shu)據為(wei)基(ji)礎,建立各影(ying)響因素(su)與砂量的模(mo)糊控制規則,采用模(mo)糊推理、模(mo)糊判斷(duan)、數(shu)學仿真分析等技術(shu)解(jie)析控制量,從而實現對上(shang)砂量的精確控制,無需人工(gong)干預上(shang)砂量。

14、電鍍液高效添加劑技術

上(shang)砂(sha)(sha)過程是金剛線生產(chan)的核心工(gong)藝流程,上(shang)砂(sha)(sha)的效率(速(su)度)直(zhi)接影(ying)響金剛線的生產(chan)速(su)度;上(shang)砂(sha)(sha)過程中金剛石微粉顆粒(li)在母線上(shang)分布的均勻性(xing)直(zhi)接影(ying)響金剛線的質(zhi)量一致(zhi)性(xing)。因此為了保證高速(su)上(shang)砂(sha)(sha)和(he)均勻上(shang)砂(sha)(sha)(不(bu)團聚(ju)、不(bu)疊(die)砂(sha)(sha)),上(shang)砂(sha)(sha)槽中添加(jia)劑和(he)使用方法非常重(zhong)要。

15、金剛石微粉鍍覆技術

金剛石微粉顆粒本身不導電,為使得金剛石微粉顆粒能夠在電鍍的機理下固結在母線上,一般是采用化學鍍的方法在金剛石顆粒表面包覆金屬鎳進行表面金屬化處理。但金剛線生產過程中的電鍍液環(huan)境(jing)是酸性的,會腐蝕(shi)金(jin)剛石(shi)顆粒(li)(li)表面(mian)的金(jin)屬(shu)(shu)鎳層,使(shi)得金(jin)剛石(shi)顆粒(li)(li)表面(mian)的金(jin)屬(shu)(shu)鎳層脫(tuo)落(luo)或(huo)金(jin)剛石(shi)顆粒(li)(li)與(yu)母線(xian)基體結合力減弱(ruo),進而降(jiang)低(di)金(jin)剛線(xian)的質量以及(ji)改變電鍍液的成分。

16、金剛石微粉后處理技術

金(jin)(jin)剛線(xian)生產過程中,在(zai)金(jin)(jin)剛石(shi)微(wei)粉顆粒固結(jie)(jie)到鋼(gang)線(xian)基體(ti)(ti)表面(mian)(mian)后(hou),鍍液中的(de)(de)鎳(nie)離子將在(zai)電鍍作用下持(chi)續(xu)移(yi)向鋼(gang)線(xian)基體(ti)(ti)獲(huo)得(de)電子還原為金(jin)(jin)屬鎳(nie),并同時將金(jin)(jin)剛石(shi)微(wei)粉顆粒固結(jie)(jie)在(zai)鋼(gang)線(xian)基體(ti)(ti)表面(mian)(mian),因此金(jin)(jin)剛線(xian)外表層的(de)(de)金(jin)(jin)屬鎳(nie)鍍層是(shi)決定了金(jin)(jin)剛石(shi)顆粒在(zai)鋼(gang)線(xian)基體(ti)(ti)上(shang)的(de)(de)固結(jie)(jie)能(neng)力,進而(er)決定了金(jin)(jin)剛線(xian)的(de)(de)切割能(neng)力,金(jin)(jin)剛石(shi)顆粒在(zai)鋼(gang)線(xian)基體(ti)(ti)上(shang)的(de)(de)固結(jie)(jie)能(neng)力是(shi)金(jin)(jin)剛線(xian)最重(zhong)要(yao)的(de)(de)技術(shu)指標之(zhi)一。